This article covers some of the most important aspects of starting a juice business.

Click a section to skip to it:

- Juice Bar & Kitchen Layout Infographics

- Kitchen Flow

- Juice Bar Equipment List

- Total Cost of Equipment

- Using a Commissary Kitchen

This article has been updated (originally published September 8th, 2016).

How to Design a Commercial Juicing Kitchen

Juice Bar and Kitchen Layouts

One of the most common questions we get from people starting a juice business is how to set up a kitchen for cold-pressed juice.

We decided to put together infographics that show simple setup, equipment lists, and flow diagrams for a cold-pressed juice kitchen and for a juice bar. You can download the free PDFs here:

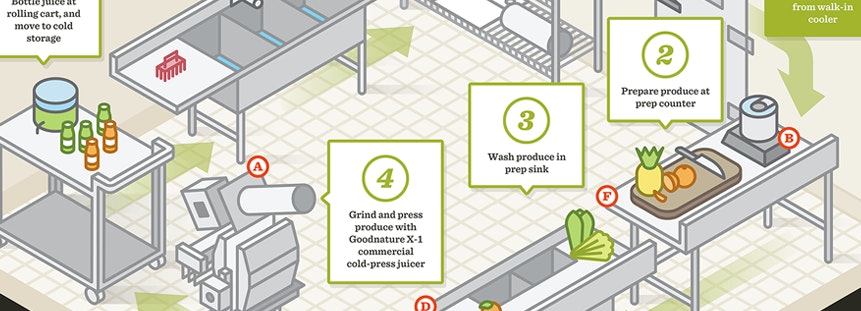

Kitchen Flow

When designing a kitchen, you need to think about the flow. How are people going to move around the kitchen? We don’t want two people crossing paths and running into each-other if it can be avoided, and we want to minimize the amount of time people spend moving around. In this example, we designed the kitchen so that the juice-making process flows in a clockwise fashion around the kitchen. Designing a kitchen in this way will make your employees more efficient and with minimum confusion in their work area.

The Juice Bar Equipment List

Some of the equipment covered in the layout examples include:

- Goodnature M-1 Commercial Cold-Press Juicer – Can make 100 bottles of cold-pressed juice per day

- Goodnature X-1 Commercial Cold-Press Juicer – Can make 1,000 bottles of cold-pressed juice per day

- Goodnature X-1 Mini Commercial Cold-Press Juicer – Can make 300 bottles of cold-pressed juice per day

- Food processor or blender is used to make smoothies and grind nuts to press nut-milks

- 3 compartment sink with sprayer – Can be used to wash machine parts, bottles, and the sprayer can be used to wash the X-1 machine

- Prep sink for produce – It’s nice to have a separate sink for washing fruits and vegetables, but optional

- Hand sink – Most health departments require a separate sink for washing hands (and nothing else)

- Prep table – Stainless steel used to prep the produce for juicing

- Drying rack – This rack is used to air-dry dishes, machine parts, and press bags

- Walk-in cooler – Produce and juice should always be stored in a refrigerated space. If possible, the entire juicing kitchen should be cooled

Total Cost of Equipment

You can expect to spend around $20,000 – $75,000 on the equipment listed above. Still have questions? Contact us!

Using a Commissary Kitchen

If you are looking for a way to save on the initial investment of a commercial kitchen, check around your area for shared kitchens that allow you to rent the space by the hour. These commissary kitchens are used by many food and beverage startups looking to use a commercial kitchen without owning the space themselves. These kitchens usually have sinks, counters, and refrigeration space. You would most likely still need to purchase the juice press and any specialty equipment. Some kitchens will allow you to store the equipment in the space even when you’re not using it. The terms and pricing vary a lot by location and business, so you will need to do your own research in your area.

Before You Go

Here are a few free articles that cover essential info for juice business operators:

- 5 Tips for Starting a Cold Pressed Juice Business

- Cold-Pressed Juice Bar Business Plans: The 4 Basic Models

- 7 Tips for Navigating Juice Bar Regulations

- How to Increase Your Juice Bar Business Profit

And if you’d like to add some delicious, chef-made recipes to your menu, browse our juicing recipes here!

Comments

I would like to know the price for the machine and do you ship to Tanzania Dar es Salaam?

Hello! We do ship direct to over 70 countries world wide. Please send an inquiry here and our experts will help you out with a quote including shipping: https://www.goodnature.com/quote

I am looking at setting up a Juice bar in St. Vincent sometime this year and looking for some guides or startup business plan.

I started up a small juicebar trailer here in Missouri. It's difficult to find organic suppliers in the midwest. Where do you suggest I go looking?

Hi Audrey, if you haven’t had a chance to read our article on the topic yet, I’ll post the link here. Also, in the article there is a link to Chef Ari’s online course where he covers this topic in depth (also a course coupon code). One of our team members will reach out to see if there is anything else we can do to help, congrats on starting your juice biz! https://www.goodnature.com/blog/how-to-source-produce-from-distributors

Please I need a guide on how to start a juice business am from Nigeria.

Hi Ebube, one of our team members will email you shortly. In the meantime, check out our articles here: https://www.goodnature.com/blog/20-must-read-articles-if-youre-starting-a-juice-business/

Really very helpful information. Thanks for sharing and please keep it up

I am a start-up with healthy juice offering and new to the business and would like you help.

Hi Saby,

One of our team members will be reaching out shortly, in the meantime, check out our articles on starting a juice business here: https://www.goodnature.com/blog/20-must-read-articles-if-youre-starting-a-juice-business/

I want to start juice business in India. need your support for equipment's details with price & setup cost (if you provide).

Hi Roompam,

On of our team members will reach out to you via email to help answer your questions, thank you!

I am in the process of preparing to open a juice bar. As a start up would two m1’s suffice?

We’ll be focusing on juice on demand primarily but also want to have the capacity to bottle for juice cleanses.

Also is there any downside to haven’t a dishwasher vs the three stage sink?

Two M-1s could definitely get you started, but if you plan on sticking a grand and go fridge and selling juice cleanse packages you will likely need a larger machine as well like the X-1 mini.

If you have a dishwasher, you will still need a 2 or 3 compartment sink. Not everything can be washed in the dishwasher, including fruits and veggies!

Hi,

I am working on opening my juice shop super excited I purchased the X1-Mini. Right now we are working on remodeling and was wondering what floor do you recommend for the kitchen we will just be juicing and making raw food. Also should we add some sort or protection to the wall to make it easier to clean?

Hi if you are moving into a place with multiple floors, it would really depend on where you have the space fro a kitchen. The X-1 Mini is fairly compact so you can move it without much of an issue. If you plan on moving up to the full size X-1 later I would definitely recommend putting the kitchen on the 1st floor.

Most commercial kitchens put either RFP or stainless steel on the walls, making them easier to clean.

Very helpful site! Please help. I wanna start a vegetable based juice and smoothie bar but (1) I don't know what equipments and materials I need to get started. I wanna start small. (2) I'm residing in Swaziland (Southern Africa) and I've just learnt that there are no juicer suppliers in my country. Any legitimate online site I can purchase from? (3) Do you guys sell juice& smoothies recipe books online? (4) Any advice you can suggest? I'd really love that...

Warm regards

Hello, you can purchase juice equipment directly from Goodnature and we can ship to Africa, we have many customers there. We do have the juicing companion book which you can find here.

My advice would be to read through our blog, there's a lot of useful information there. Good luck!

Hello my name is Pixie Guzman from San Diego

I am reaching out because I love and admire what you do for others ! I am planning on opening up a smoothie bar here in SD and I could really use some of that pro advice ...

I am unsure of the proper equipment needed for an up to code commercial kitchen for a smoothie bar. It might be similar to the above , but any new advise, links and tips are appreciated ! thank you

Hi Pixie! You should check out the X-1 Mini which is a great juice machine for a new juice company.If you need expert consulting, you can check out our consulting page.

For the smoothies part, how does one deliver to customers not on premise? By bottle or cups? If by cups, how does one manage carrying them without spillage and easy defrost

If smoothies are delivered it is usually in cups with a lid. Smoothies are tough for delivery because they need to stay very cold or they will melt.

Great blog & info.

What is the juice yield of common fresh herbs (chives, coriander, dill, parsley, ..). I mean how many kilogramms of fresh herbs I need to produce 1000 (500ml) bottles?

Thanks in advance

M. Osman

You can expect to need about 1.5 lbs - 2.0 lbs of herbs to make a 500ml bottle of juice. So for 1000 bottles you could expect to need up to 2,000 lbs of herbs.

Hi,

How many people do you think should be working in the whole process -from the begging to bottle- considering that you will be processing 1.000 bottles. Thank you very much for your response.

If you are making 1,000 bottles per day on an X1, you will need 3 people. One person to wash and prep the produce, one person using the juicer, and one person bottling.

Very well written, but what would you recommend to actually package the bottles?

Do you mean the bottles? You casn use either glass or plastic bottles. If you are ordering plastic bottles in the US, you can use our app here: https://www.goodnature.com/bottle-up/

I noticed you don't have a bottle filler, do you need one for the X-1? I would like to be able to bottle juices and ciders, what would you recommend? Also, how would you keep the juice from air exposure?

A bottle filler is only needed if you are filling thousands of bottles of juice per day. That's because the automated bottling line is really the only type that saves time.The semi-auto fillers that operate with a foot switch don't save much time, and cause some wasted juice.

Hi Charlie,

What's the best way to wash fruits and vegetables (knowing that the juices are raw with no hpp process)? By hand with a brush (it take's a lot of time)? With a vegetable washing machine (http://www.firex-foodequipment.com/catering-machinery/professional-kitchen-appliances/vegetable-washer)?

You don't speak about a vegetable washing machine in your kitchen layout, so i was wondering if it's worth to invest in this kind of machine to save time for washing or doesn't it wash the vegetables well and you do need to wash them by hand ?

Sebastien, usually companies switch to automated washing when they get to be fairly big, and not when just starting out. Washing by hand will be fine until you are doing thousands of bottles per day, at which you will need to get an automated conveyor system. The machine you linked to seems like it might speed things up a little bit, but not by much. I think for now you can just wash by hand in a sink using a produce washing solution like ecolab victory wash.

Hi Charlie, Your entire blog has very useful info. Thank you for all the great posts. Do you have a similar doc suggesting a layout for the CT7 when used on the shop floor?

Hi Elise, we haven't put one together for the CT7. We would be happy to help you with your shop if you have a layout of the floor plan. Thanks!

Thank you for this visual, what is the square footage, as seen in the infographic.

12ft x 12ft

my question before i consider buying a cold press commercial juicer ,is it a way of pasteurizing juice or i have to find different way to pasteurize it .

Pasteurizing is a secondary step which requires additional equipment. Look into HPP.

Hi, how much costs the X1? and what other models do you have?

Thanks

Hi Javier! To get a quote for our machines, please visit our contact page here: https://www.goodnature.com/contact. For more information about our machines, you can learn more here: https://www.goodnature.com/pressing. Thank you!

We love our X-1! Now this will help us design our kitchen around our great machine. Thank you!

Thank you as well Wendy! We're very glad and happy to hear that about the Goodnature X-1!

Hi how much does your commercial countertop juicer cost?

Starting my business won't demand 1000 bottles a day. If and when I want to upgrade to the X1 is there any trade in or upgrade deal with your company?

Thank you for great advice.

Chelsea Coetzee

Organicruz LLC, Owner

[email protected]

Hi Chelsea! One of our account executives will be emailing you answering your questions and any additional questions you might have.

How do you calculate that how much equipment is needed to get 1000 bottles of juice. And can you share the layout of juice truck

Very helpful. Can you give an idea of the area measurements for the layout. Thanks.

You should be able to do this in a 12' x 12' space

Hi there! How many hours are you suggesting 1,000 bottles should take? And with how many employees and how many different recipes? Thanks!

You can make 1,000 bottles (500ml ea) per day with 3-4 employees in an 8 hour work day. If you follow the process and flow outlined in this infographic it will make things organized and efficient!

We love juicing business kindly; send me more details in this regards

Regards

Abdulkader Demachkieh

Cofounder and CEO of Aldro for Home and Kitchen Appliances Trading L.L.C

00971 55 517 0841

Hi Abdulkader! One of our account executive will send you more information with the email that you provided.

This information is very helpful. Thanks

Comment