If the ReadyGrind™ Kit is hard to remove on your M-1, it is often caused by the Grinder Blade being hard to add or remove from the Grinder Motor Housing. Follow the steps below to troubleshoot:

Step One

Turn the power switch to the OFF position.

- Are all screws screwed in all the way? Do not try loosening them, this usually is not the problem unless they have been replaced in the field and overtightened. They come from the factory installed to the correct torque and spacing.

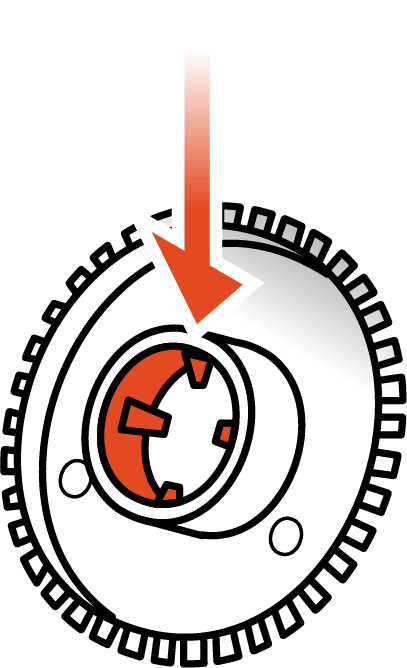

- Try Installing and removing the Grinder Blade onto the Grinder Motor Housing by itself. Is it hard to slip on and off? Some blades fit tighter than others.

Possible fixes if the blade is getting stuck / hard to remove by itself:

- Small amount of sanding to the inside of the plastic drive grip (located on the underside of the Grinder Blade). It doesn’t take much smoothing of the plastic to change how tight it fits.

- Installing a new or tight Grinder Blade 20 times will break in tight spots.

- If under warranty, a replacement blade can be sent. A new Grinder Blade might also fit tight if it is the drive tip (metal motor end that sticks out of the Grinder Motor Housing) that is slightly large. If that's true, the only solution will be a slightly loose Grinder Blade.

Step Two

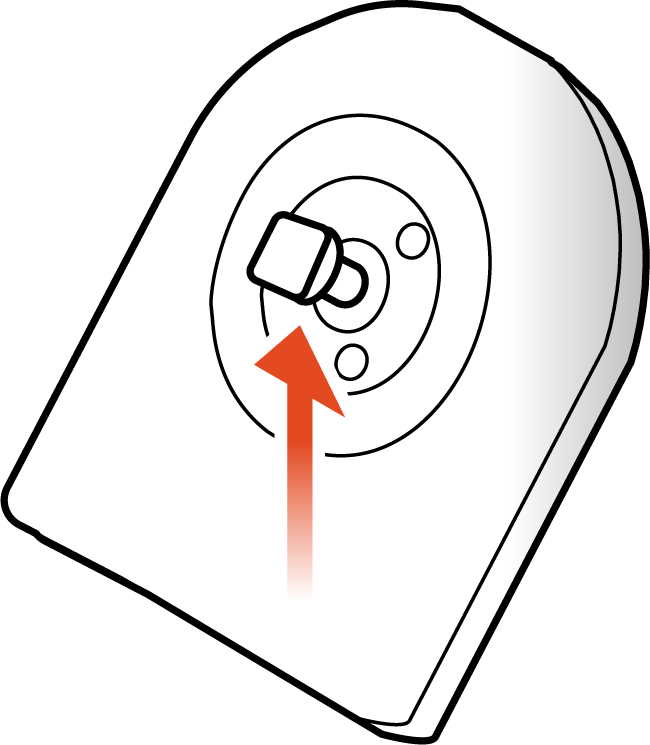

If the Grinder Blade is not the cause of the problem, move on to the Hopper Base.

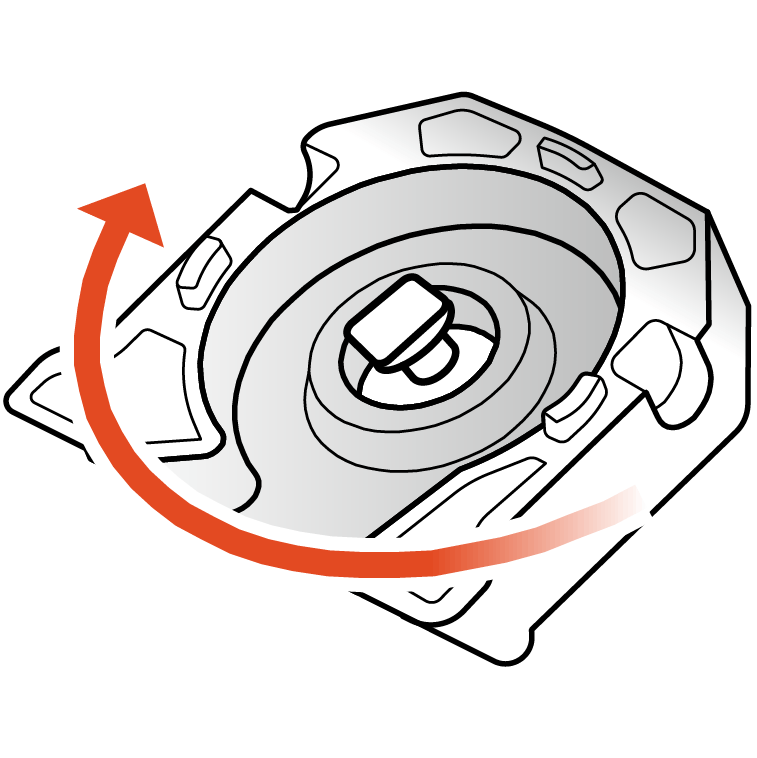

- Install and remove the Hopper Base, by itself. Due to variation in molding and production some Hopper Bases will fit slightly more snug.

- If there is a high spot on the Hopper Base, twisting and untwisting to install and remove it 20 times should reduce the issue to an acceptable level.

- If under warranty, a new Hopper Base can be sent.

If issues persist after these troubleshooting steps, consult with engineering on next steps. For technical support needs, contact our technical support team.