Let’s start with a single question quiz:

Amy needs to produce 40 bottles of juice. Her commercial juicer is rated to produce a maximum of 40 bottles of juice per hour. She is juicing by herself. How long will it take her to make the juice from start to finish?

A. 30 minutes

B. 1 hour

C. 2 hours

D. 3 hours

E. 4 hours

Ok, choose your answer…

What did you choose?

If you chose A, what were you thinking? That is so, so wrong.

If you chose B, you are also wrong but not embarrassingly wrong like you would be if you chose A.

If you chose C, you might be right if Amy is a superstar juice maker.If you chose D, or E, congratulations, you passed! You are now a certified (albeit, slow) juice maker.

Here’s an insider secret— few operations are actually achieving the maximum output of their commercial juicer. In order to understand why, let’s start with thinking about a juicing operation from a high level. There are several steps in the process including:

- Weighing produce

- Washing produce

- Prepping produce

- Juicing

- Bottling

- Applying labels to bottles

- Stocking bottles in cooler

- Cleaning equipment and kitchen

Notice how many of the steps actually include making juice? Yup, just one. The actual juicer is only a small part of a juicing operation. The juicing is not the most time consuming part of the process.

If your juicing operation is a one man / one woman operation like Amy’s, chances are you are spending far more time weighing, prepping, bottling, cleaning etc. than actually making juice.

Now let’s look at the best ways to increase your hourly production rate and get closer to the maximum rated hourly output of your juicer.

Organization

The more work you do ahead of time with organizing the production, the more efficient the production process will be. How well you organize the kitchen flow, the cleaning process, the weighing process, etc. all comes into play. Try to improve your process every time until you feel like it’s right.

Some things that should be ready to go before you start the juicing:

- Everything should be clean – including the juicing equipment. You shouldn’t need to clean anything except the produce before starting the process.

- Smallwares should be where they belong. Don’t leave yourself in a position to need to “find things” while juicing. Put everything in its place before starting the process. Including cutting boards, knives, bottles, etc.

- Recipes and batch information should be prepared for the day. Printed is usually best, but displayed on a screen is fine too. Spend the extra time the day before to plan.

Pro tip: Goodnature commercial juicers work on their own while they’re pressing. You don’t need to be waiting near the machine. Use this time to complete some of the other steps of the process. If you find yourself standing around with nothing to do while the machine is pressing, you could probably be planning better.

Organization includes how your kitchen is designed— if you find yourself running around a lot, you might be able to better design the flow. Don’t be afraid to move things around; refrigerators, carts, bins, even sinks if needed (you’ll need a plumber for this). Check out one of our kitchen layouts for a good place to start for kitchen layout.

Workforce

Once you feel like everything is organized, planned, and efficient, try to get some help. Find the bottlenecks in your operation, and have someone fill in to help out.

While one person is prepping, another person can be juicing and bottling. Once the prepping is done, the prep person can move to clean-up. The addition of even one person can make such a big difference in the juicing process.

Once you have two people operating pretty well, try to look at the process again, and notate any moments you see one of the people standing around with nothing to do. There is certainly something they could be doing. If both people are busy but you still have bottlenecks, it may be time to add third person (if your goal is faster production).

Produce Type and Yield

Another very important point is that produce varieties vary greatly in how much juice can be squeezed out of them. Juicy cucumbers can generate literally twice as much, or even more, juice than carrots.

Even the same type of produce can vary based on seasonality and ripeness. The same type of fruit may change by about 30%-40% depending on the batch.

So, in an operation making primarily juice from juicy things like apples, celery, and cucumber, the hourly output may be a lot higher than if the recipes are not-so-juicy things like carrots, beets, sweet potato, etc.

If your goal is to increase your hourly production, take a look at your recipes and see if there’s any adjustments you can make to use more juicy items.

If you feel like you’re stuck and need help achieving better hourly production, we’re here to help! We have helped literally hundreds of juice bars, juice delivery companies, and other juice businesses plan and increase their production. Check out our consulting services for more info.

Comments

Thanks for these great articles! We now are proud owners of three x1 mini's! do you have batch recipes for the standard juices that will maximize each batch in the X! mini? I know all of the recipes online are for 12 oz, but I wonder if you have them calculated for the maximum load?

Thanks, We prefer to weigh out all the produce based on how many bottles total you are going to produce, then mix and grind best you can to fill the press chamber each batch rather than weighing out exactly 5 pounds of produce multiple times as a batch. Does that make sense?

Hi Katie, As Ari mentioned, its best to scale up the recipe based on how many bottles/servings you want to make total. In order to do this, just take any of our recipes (you can find them all here: https://www.goodnature.com/recipes/) and multiply the ingredient amounts by the number of 12 oz servings you want to make in total. If your bottles are larger or smaller than 12 oz, just take the total ounces you want to make and divide by 12oz and that will tell you what number to multiply the ingredients by. Hope this helps 😄

Thank you for this post! I've been looking for ways to increase efficiency and productivity for my juice operation. In 2020 due to the pandemic my juice catering business was left without any gigs so I was just juicing for myself and some family members. But since August of last year I've been doing juice pop ups around LA and started bottling my juice, it's a whole different ball game!

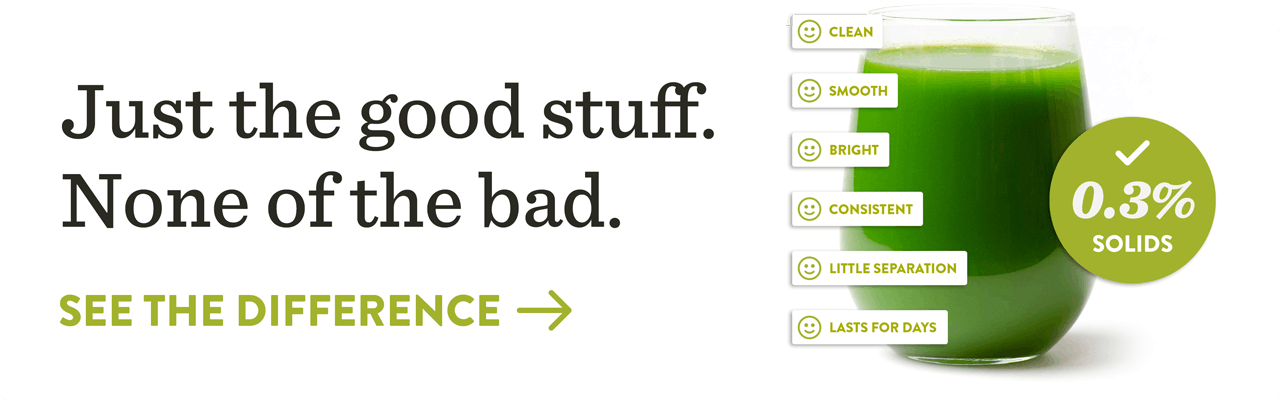

is there a major difference in centrifugal juicer vs cold press ?

Yes, the juice is very different between these technologies. Checkout this article

Comment